Our Channel Strip Heaters are dependable and reliable flat heating elements – designed to provide efficient heat to flat surfaces from common to industrial applications. Our maximum

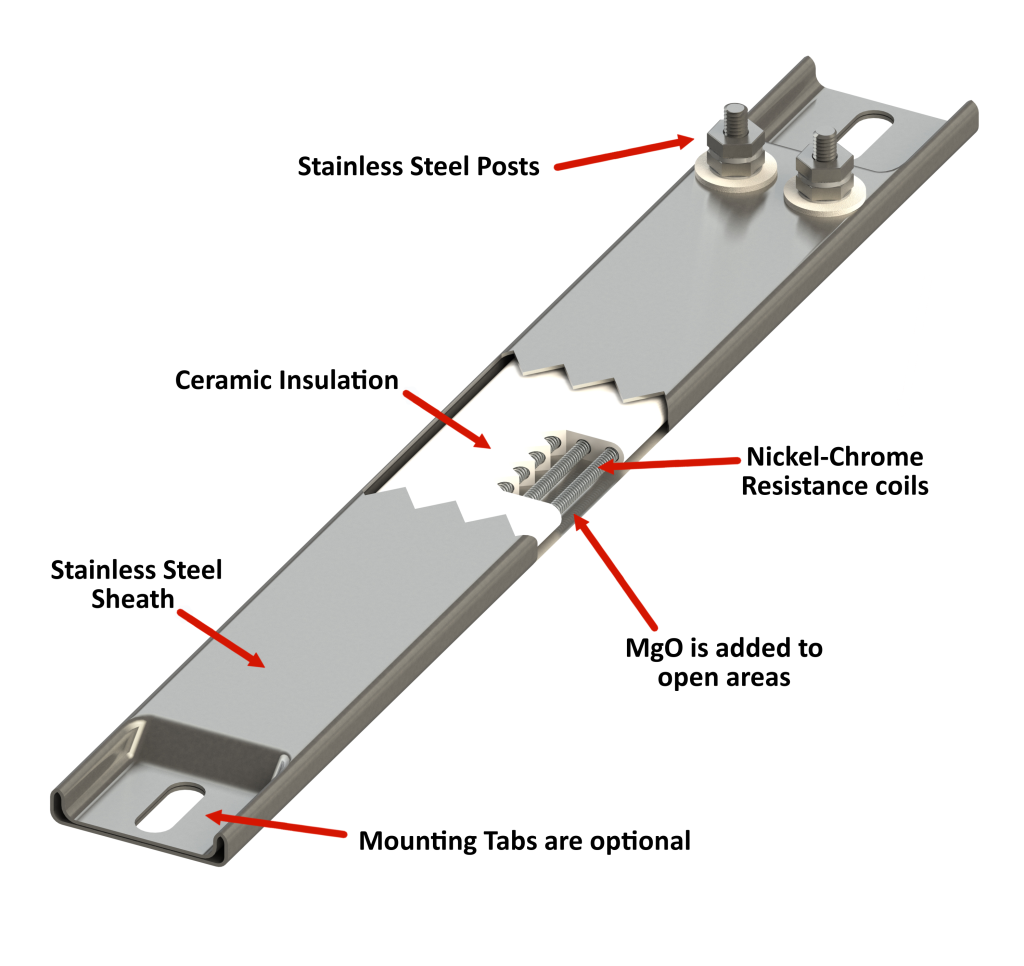

Our Channel Strip Heaters are dependable and reliable flat heating elements – designed to provide efficient heat to flat surfaces from common to industrial applications. Our maximum available channel length is 20 feet. The seamless sheath design of Channel Strips makes them ‘dimensionally’ stable in milled slots. Channel Strips are constructed with a stainless steel rectangular tube with a 1.5” x .312” rectangular dimension and a wall thickness at .030″. The inner construction consists of wound nichrome resistance coil. The inner flexible wire is strung through ceramic insulator pieces. The coils are attached to the screw terminals, or high temperature lead wires, for a positive connection. MgO (magnesium oxide) is used to fill and pack open areas surrounding the coils. The MgO material helps increase the elements thermal conductivity and dielectric strength.

available channel length is 20 feet. The seamless sheath design of Channel Strips makes them ‘dimensionally’ stable in milled slots. Channel Strips are constructed with a stainless steel rectangular tube with a 1.5” x .312” rectangular dimension and a wall thickness at .030″. The inner construction consists of wound nichrome resistance coil. The inner flexible wire is strung through ceramic insulator pieces. The coils are attached to the screw terminals, or high temperature lead wires, for a positive connection. MgO (magnesium oxide) is used to fill and pack open areas surrounding the coils. The MgO material helps increase the elements thermal conductivity and dielectric strength.

Applications: Ovens, Hot Plates, Clamp-on water heating, Coffee urns, Vacuum pumps, Vulcanizers, Autoclaves, Core baking ovens, Space Heating, Pre-Heaters, Food Warmers, Dies, Mold heating, Valve houses, Pipe lines, Process welding, Platens, Melting, Baking, Tank Heating, Incubators, Air Heating, Ink drying, Crane cabs, Sealing Bars, Load Bank resistors, and Packaging.

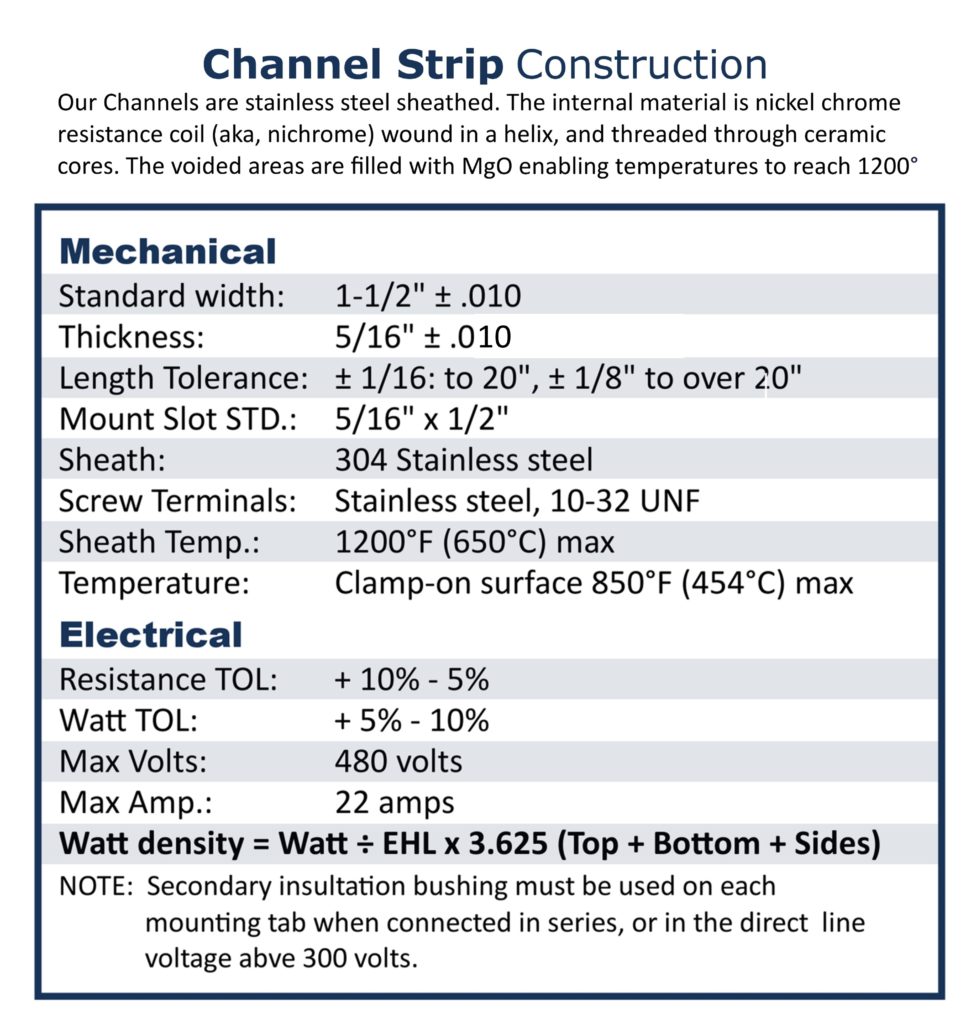

Specifications and Tolerances:

-

Strip dimensions: 1-1/2” x 5/16”

-

Outer width:1-1/2″ ± .010

-

Mounting Slot HOLE Size: 5/16” x ½”

-

Thickness 5/16 ± .010

-

Length tolerance: ± 1/16″ to 20″, ± 1/16″ over 20′

-

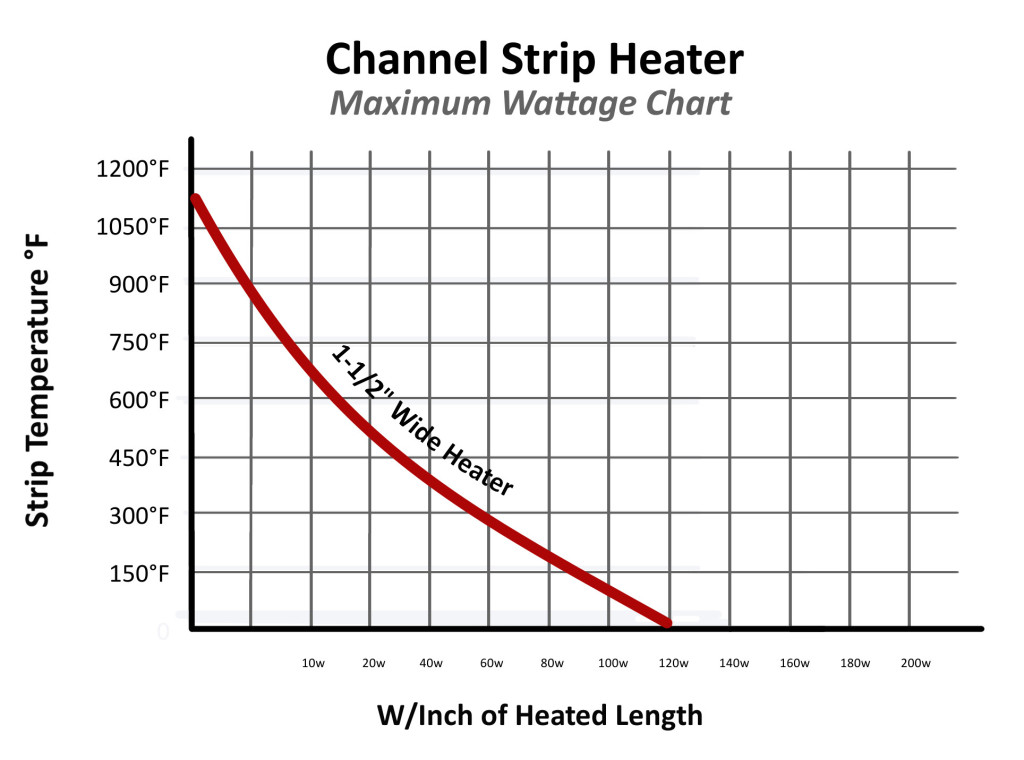

Max sheath temperature up to 1200°F (650°C)z

-

Temperature Clamp-on surface 850°F (450°C)

-

Max Voltage: 480 VAC (depending on design parameters)

-

Max Lead Voltage recommended at 240 VAC

-

Max Amperage: 22 amps (for lead wire termination 10 amps)

-

Max screw terminations 10-32 UNF-25 amp

-

Resistance tolerance: +10% -5%

-

Wattage tolerance: +5% -10%

-

Recommended Wattage Max clamped to part in 70°F ambient air (multiply by 75% if insulated)

-

Wattage Density (nominal) 45 w/in²

Channel Strips: See All our complete Channel Strips for the terminal design that meets your needs.

Please call us EST 8-5 pm for any additional custom variation requirements: 513-228-0481.

Customized Options: For liquid immersion applications, we recommend a welded option with tube based leads. The welded end design is the best to prevent MgO leakage, and to ensure all internal components remain uncompromised by a changing external environment. If you require an alternate lead configuration not displayed, please contact us to design a custom solution that meets your needs.

Standard Options: We can build our Channel Strips with standard mounting tabs, or design custom mounting tabs as required for our customers. When mounting tabs are not requested, ends are welded shut to prevent moisture and contaminant damage. Our Channel Strips are available with the following standard options:

-

Threaded Terminals

-

Leads mounted at ends

-

Leads mounted on surface

-

Lead Styles: Plain / Braided / Armor / T-Box

-

With mounting tabs

-

Without mounting tabs

-

With or Heat and Sensor Technology’s unique bulkhead design of bulkhead fittings.

-

Without bulkhead fittings

Mounting Installations: Channel Strip heaters must be clamped securely along a smooth metal surface (along their complete length). When a Channel Strip is supported by mounting tabs, ensure that the terminal is secured firmly, and that the opposite end remains loose to allow for expansion. Do not over-tighten nuts when installing, as over-torquing terminals will create internal heater damage.

Our Product Lines are US made. Call if you are in the area – and you would like to see our products: 513/228-0481.

Heat and Sensor Technology 627 Norgal Drive Lebanon, OH 45036

Phone: 513-228-0481 Email: info@heatandsensortech.com