Mass Customization

Mass customization is a strategic business offering that’s been gaining increasing presence throughout the manufacturing industry. Mass customization can be defined by the following elements:

- Providing flexibility and personalization to customers with reasonable unit pricing – that is a typical benefit of mass production and manufacturing..

- Equipping the customer with tools that enable designing – for the customer to create unique built to order products.

- Delivering global goods and services that can be modified to meet specific customer requirements.

At Heat and Sensor Technology, our Mass customization potential is broadened by our 3-D Configurator programs. Our online Configurator programs enable customers to design their custom products in single or multiple quantities.

A main objective behind offering our Configurators, was to equip our customers with design possibilities – resulting in virtually limitless custom products – when using our Configurator programs.

Our Configurators serve us by interpreting the exact User needs we can confirm with our customers. With clarity in requests, we partner better with our customers – to jointly find solutions to match their specific requirements.

At Heat and Sensor Technology, we embrace technology. And our efforts are to continue as a premier business example in our industry – with how we model Mass Customization for our customers.

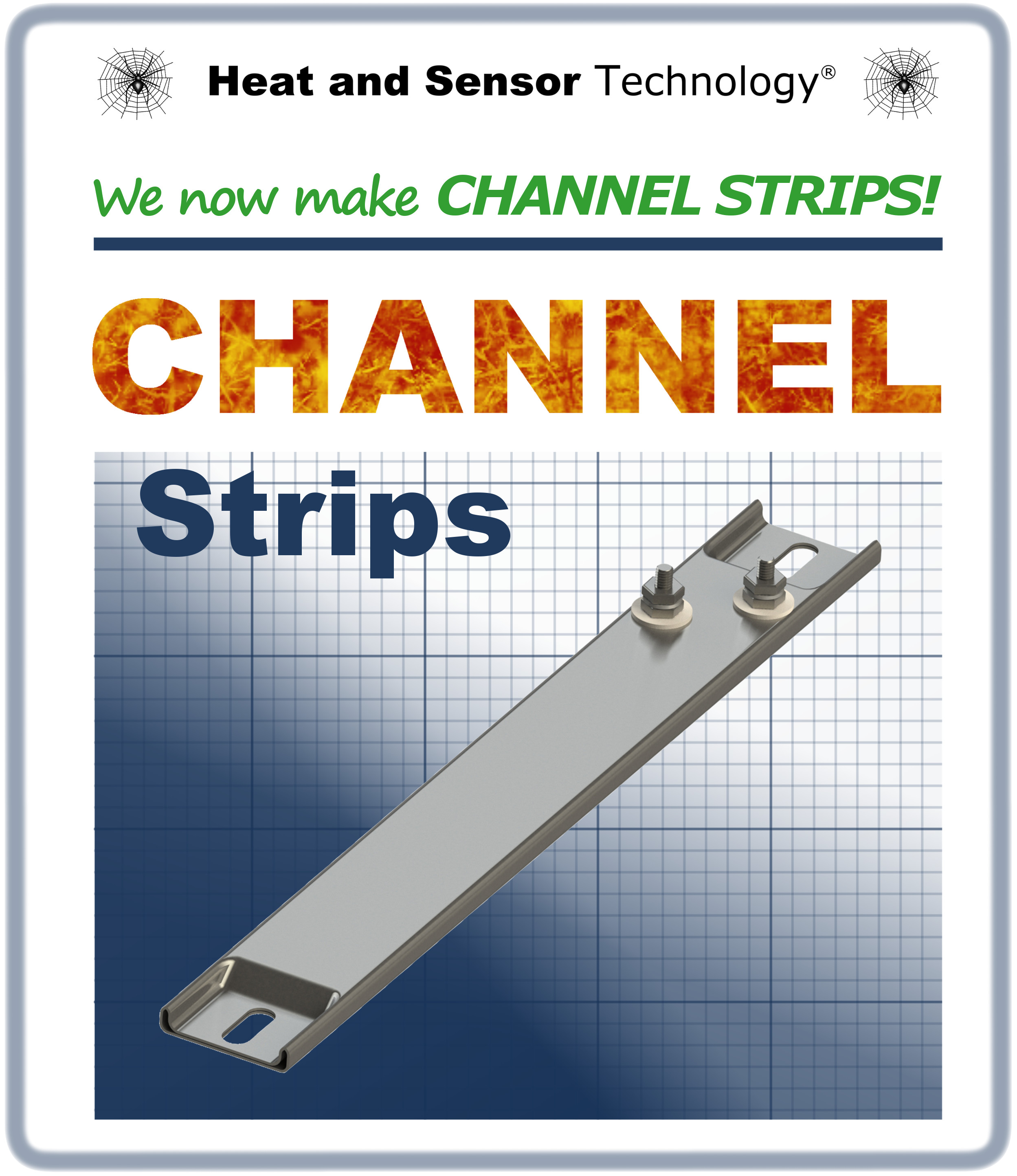

Channels Strips Are HERE!

We began making our Channel Strip Heaters at the end of October 2014. We currently offer 15 standard Channel Strip Options (click here for the descriptions) are viewable from our Channel Strip Options page. We can also offer custom designed mounting tabs, as well as our standard stock tabs. And should a customer require a lead configuration – that’s not represented from our Channel Strip Options page, we’ll design a customized solution to meet those needs.

Our Channel Strips are dependable and reliable flat heating elements designed to provide efficient heating – to flat surfaces, from common to industrial applications. Our Channel Strips are standardly constructed from a stainless steel rectangular tube with a 1.5” x .312” rectangular dimension, and a wall thickness at .030″. Our maximum available channel length is up to 20 feet.

Channel Strip heaters can fulfill a variety of applications including: Ovens, Hot  Plates, Clamp-on water heating, Coffee urns, Vacuum pumps, Vulcanizers, Autoclaves, Core baking ovens, Space Heating, Pre-Heaters, Food Warmers, Dies, Mold heating, Valve houses, Pipe lines, Process welding, Platens, Melting, Baking, Tank Heating, Incubators, Air Heating, Ink drying, Crane cabs, Sealing Bars, Load Bank resistors, and Packaging.

Plates, Clamp-on water heating, Coffee urns, Vacuum pumps, Vulcanizers, Autoclaves, Core baking ovens, Space Heating, Pre-Heaters, Food Warmers, Dies, Mold heating, Valve houses, Pipe lines, Process welding, Platens, Melting, Baking, Tank Heating, Incubators, Air Heating, Ink drying, Crane cabs, Sealing Bars, Load Bank resistors, and Packaging.

See our Channel Strips Article: Channel Strip Heaters Defined for more specifications and option details.

We want to care of your Channel Strip needs. Please don’t hesitate to call us:

EST, 8 am -5 pm: 513-228-0481, to discus your Channel Strip requirements.

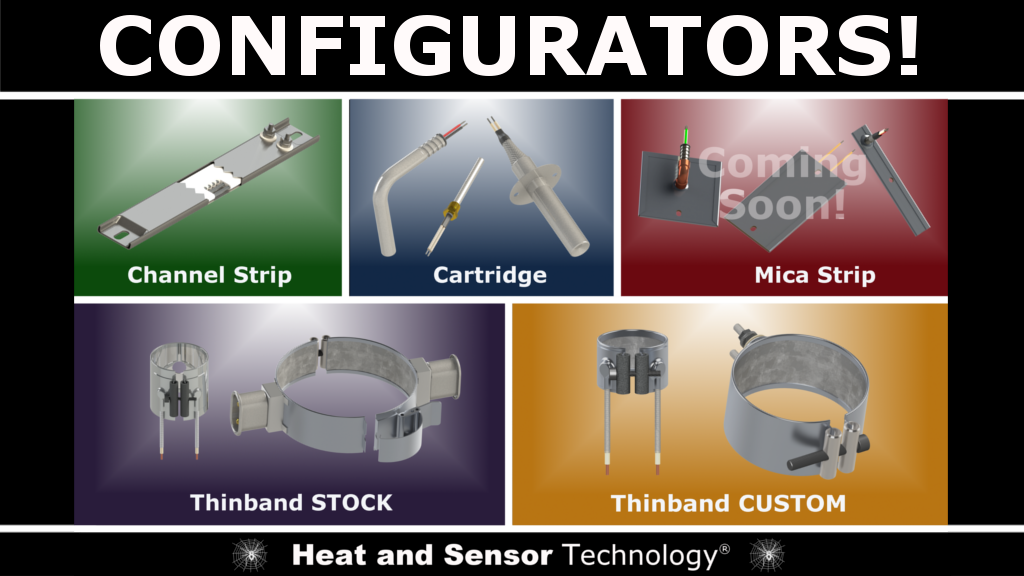

Our Configurator Family is Growing!

The Owners of Heat and Sensor Technology have had a particular long-time vision – to implement premier technology with our Configurator programs. Our goal began using DriveWorks software to design Configurator programs – for building heaters… online, and especially for use by Distributors and OEM businesses.

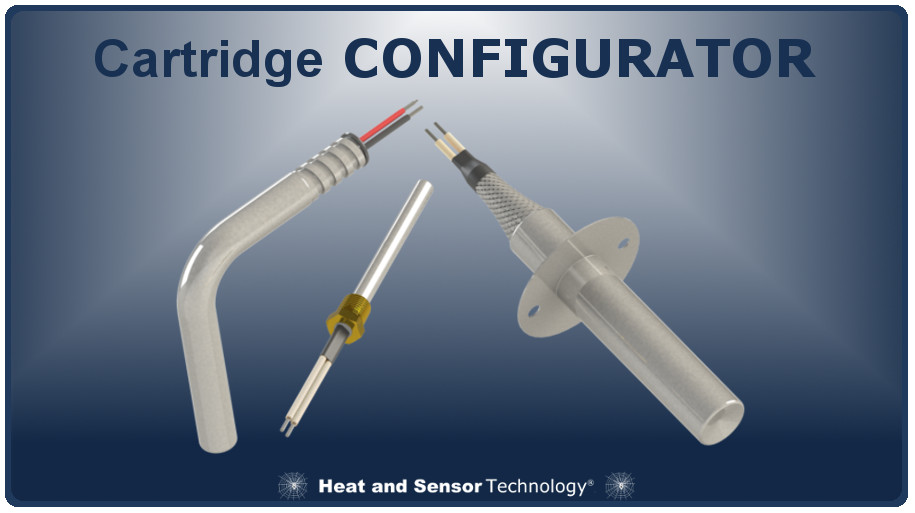

We began to realize this dream in May of 2014, with the launch of our Thinband Stock Configurator, and our Thinband Custom Configurator. And before the year closed, we launched our Channel Strip Configurator (November, 2014). Keeping up our momentum, in February of 2015, we launched our Cartridge Configuator. What’s next? The Mica Strip Configurator will be next… and just in time for the NPE2015 show!

We feel our Configurators are a benchmark of achievement – representing excellence in customer service that we’ll continue to develop. Our customers have convenient access when they want to build a heater, 24/7 – right from our Home page. The appealing benefits of our programs are: Customers can manipulate and examine the 3-D image of their design – before placing an order. And once a customer completes their design, and clicks the quote button, they automatically receive an emailed quote and drawing of their built heater.

If you too would like to test a Configurator, please don’t hesitate to call us: EST, 8-5 pm: 513-228-0481, for your personal USER & PASS access codes.

We will be exhibiting at NPE2015 this year!

For those attending this March 23-27 NPEShow in Orlando, Florida, please stop by our booth: S19147. We will have samples ofall our product lines: Thinbands, Channel Strips, Cartridges, Mica Strips, Mica Bands, Ceramic Bands, Thermocouples and Tubular Heaters, all available for up-close handling, and for product Q&A. All visitors are welcome to test our Configurators – from both front corners of our booth!

For those without an NPE2015 Pass – click here for your free GUEST PASS from Heat and Sensor Technology!

See our Configurators featured on DriveWorks’ Configure & Automate Blog.

Coherent Laser Cutting Machine

Heat and Sensor Coherent Laser Cutting Machine

5/2014

Heat and Sensor Technology is dedicated to improving and implementing quality products and software that improve both quality distribution and customer service.

Lebanon, Ohio, May 2014 – Heat and Sensor Technology is continually committed to improving the quality of products and related software. Key examples of progress improvements applied throughout their business include: Customer Service, Employee Training, and Innovative Machinery.

In May of 2014, one of Heat and Sensor Technology’s largest capital machine investments – their Coherent Laser Cutting Machine by MetaBEAM™. This versitile Coherent Laser Cutting Machine meets CE compliance directives and standards. This Coherent Laser Cutting Machine is designed to cut and engrave a wide range of materials, and features the peripheral equipment: Dust collector, Oxygen tank, CAD software/Nesting software, and HMI Interface (computer, touch screen monitor, keyboard with mouse).

Though the incorporation process of the Coherent Laser Cutting Machine took a few months (additional equipment was needed during the process) the capabilities of this laser machine have been well worth the investment. The Coherent Laser Cutting Machine continues to benefit Heat and Sensor Technology by dramatically reducing production time, improving quality, and enabling limitless creation of customized parts.

Heat and Sensor Technology

627 Norgal Drive Lebanon, OH 45036

Phone: 513228-0481

Email: info@heatandsensortech.com

New Technology for Custom Heater

Heat and Sensor Technology Offers Stock and Custom

3-D Configurators

5/6/14

Heat and Sensor Technology is the first in their industry to offer customers heater designing via their 3-D Configurator Programs. The business has just launched their second Configurator Program which offers customized design capabilities, also with 24-hour customer accessibility. OEM and Distributor entities can utilize both Configurator programs directly from the company’s website home page, to more concisely recommend optimum heater solutions for their clientele.

Lebanon, Ohio, May 2014 (American Media Distribution) – Heat and Sensor Technology developed their Configurator programs using state of the art C.A.D. DriveWorks LTD© software to significantly assist current and future customers with their heater design needs. The Configurator programs function as tools providing Users convenient at-will access, and ease of use, when selecting components to meet heater design requirements. The Stock Thinband Configurator (the first developed) contains solely stock inventory options for building Thinband heaters. And the Custom Thinband Configurator contains inventory for customized component design, including for example, additional sizes, wattage, and voltage options.

Visitors utilizing the configurators will find the functionality of the programs to be straightforward. In the initial visit only, pop up screens direct Users throughout the selection process, and to where their information can be saved for future visits. In the last screen of the program, a preview box, with a link of the same name, allows Users to view and manipulate their 3-D design. After their rendering materializes, Users can immediately use their mouse tool to move, rotate, and view all angles of their heater design. At this portion of the program, Users can visually inspect and confirm their heater is correctly assembled. If revisions need to be made, Users can simply click a back arrow to revise their heater. Once a rendering is correct, a click of the quote button generates an immediate email (to the User) containing their quote and heater drawing.

Program Home: This page is where Users can choose from either the Stock or Custom Configurator to begin the selection process for building their heater.

Heat and Sensor Technology is a company built upon more than 20 years of knowledge from large corporation experience in the designing and manufacturing of heaters. Heat and Sensor Technology’s foundational intent (since their 2002 beginning) was to draw upon their heater manufacturing experience, and make mass customization of premier heaters available to audiences around the globe. This mindset continues from initial request, through the delivery of each of the company’s heater styles: Thin Bands, Mica Bands and Mica Strips, Ceramic Bands, Cartridges, Thermocouples, Channels and Tubulars. Heat and Sensor Technology continues to model their intentions with a premier presence. The company continues to utilize and offer state of the art technology applications, including their 3-D Configurator Programs, to better partner and serve their customers around the globe.

Interested OEMs and Distributors can contact Heat and Sensor Technology by Phone: 513-228-0481, or Email: info@heatandsensortech.com, to receive User and Pass codes to test both 3-D Thinband Configurators. The Stock Thinband Configurator can be examined when visitors enter the word: GUEST in the User field (no Password is needed). Both Configurators are accessible directly from the website home page: www.heatandsensortech.com.