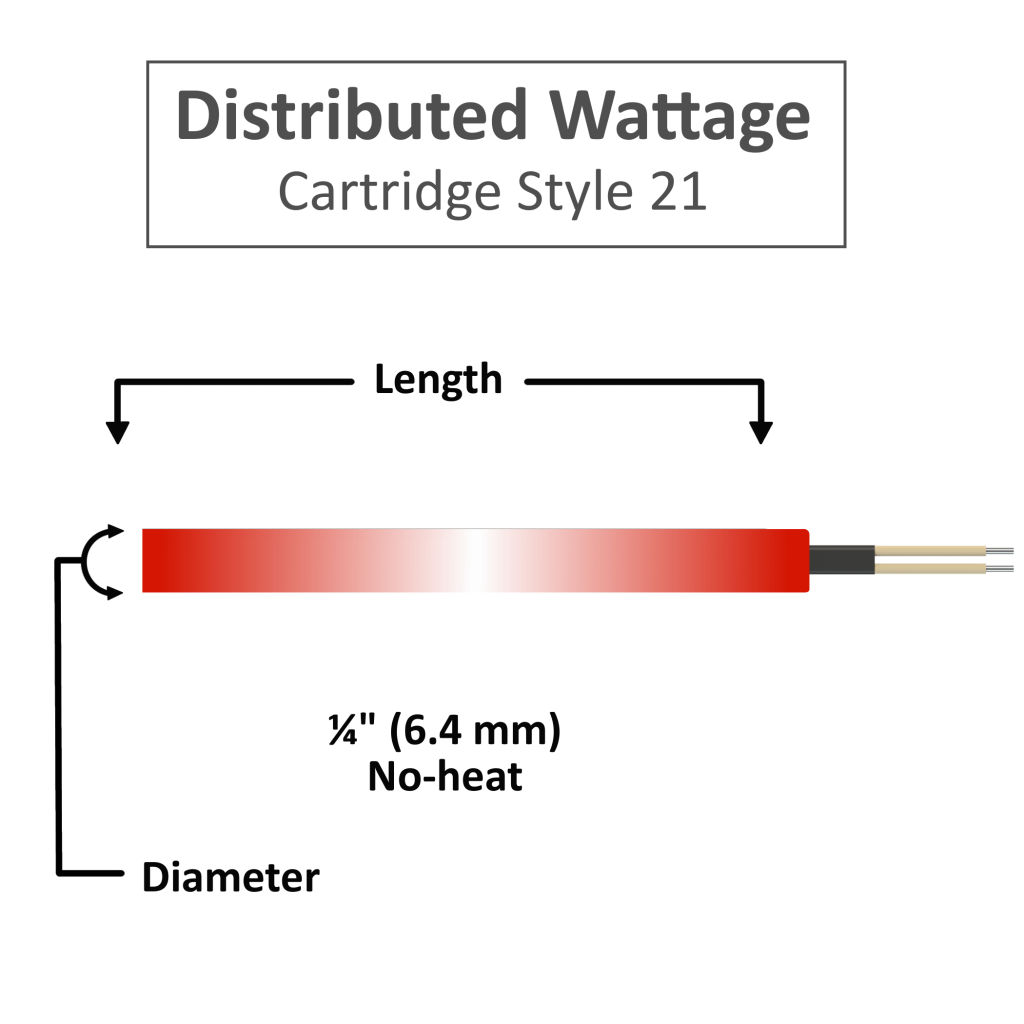

Cartridge heaters are tube-shaped, heavy-duty, industrial joule heating elements (electrical resistance) used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Cartridge Heaters provide superior heat transfer with uniform temperature and resistance from oxidation and corrosion at high temperatures. Our popular Cartridge heaters are the following design styles: Straight, Right Angle, Flange, 90 Degree, Posts out Both Ends, Post on Same End, and Distributive Wattage. Click to see our full line of: Cartridge Heaters

Cartridge Heater Applications: Molds, Platens, Dies, Hot Plates, Sealings, Aerospace, Fluid heating, Life sciences, Semiconductors, Foodservice equipment

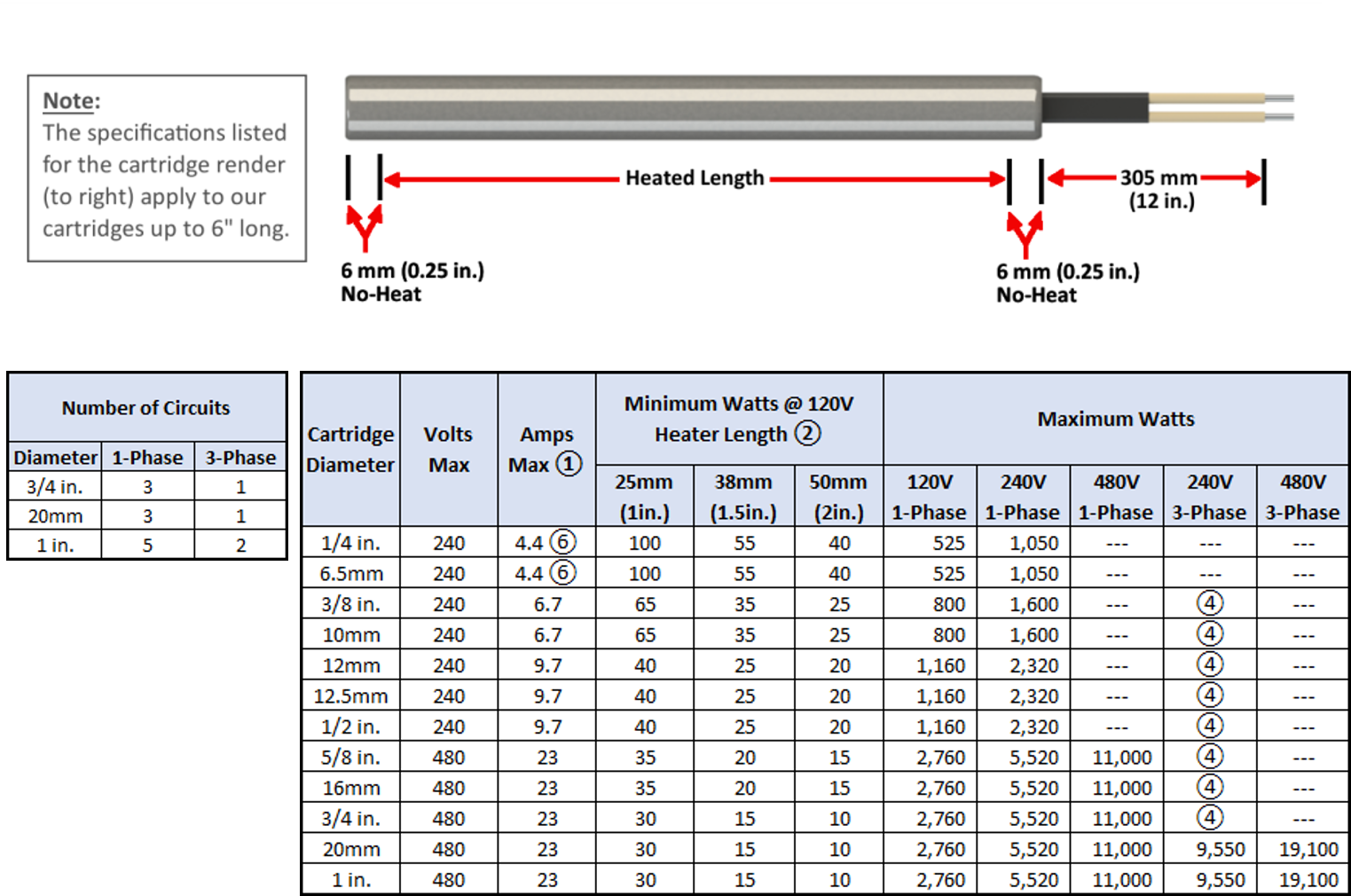

Cartridge Heater Specifications:

-

304 Stainless Steel Sheath

-

All heaters are swaged at 3/6 L for immersion applications

-

Watt densities (guaranteed to 150) up to 200 W/in² (62 W/cm²)

-

Part temperatures to 1000° F (540°C) for optional stainless steel sheath

-

Part temperatures to 1400°F (760°C) on Incoloy® sheath

Cartridge Heater Standard Tolerance Chart:

Diameter:

-

1 inch units: ±0.003 inches (±0.076 mm)

-

All other units: ±0.002 inches (±0.0508 mm)

Length:

-

All units up to 4 1⁄2″ (115 mm) long: ±3⁄32 inch (±2.4 mm)

-

All other units over 4 1⁄2″ (115 mm) long: ±2 percent

Wattage:

-

All other units: +5 percent, -10 percent

Resistance:

-

All other units: +10 percent, -5 percent

Three circumstances where resistance can be measured:

1. Temperature of room before use; nominal ohms are 90 percent of ohm’s law calculation.

2. Temperature of room after use; nominal ohms are 90 percent of ohm’s law calculation.

3. Temperature during use – depending on the application; nominal ohms are 00 percent of ohm’s law.

Our Product Lines are US made. Call if you are in the area – and you would like to see our products: 513/228-0481.

Heat and Sensor Technology 627 Norgal Drive Lebanon, OH 45036