We manufacture thermocouples for General Application purposes. Our thermocouples are utilized primarily by the Plastics Industry. Thermocouples are sensors, or temperature measuring devices, are the most commonly convenient and versatile tool for measuring temperature. Thermocouples function to convert units of heat into useable engineering units that serve as input signals for process controllers and recorders. Thermocouples are suitable to be used in temperature ranges from (-200 to 2316) °C [-328 to 4200] °F.

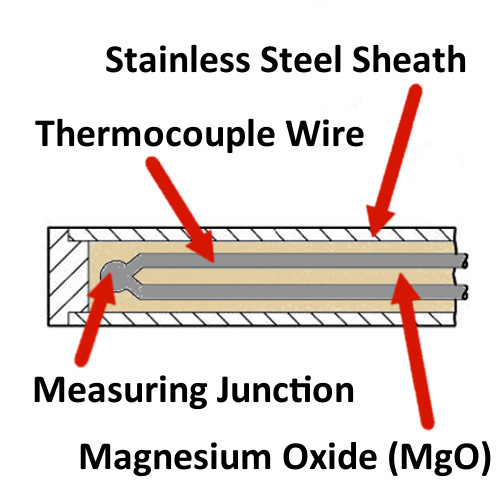

Thermocouple construction is the pairing of two dissimilar  metals or alloys (commonly available as wire) that are welded together at one end to create the thermocouple Junction. It is the heating or cooling of the two metals that produce a voltage which can be correlated back to the temperature. More basically, thermocouples are the construction of wires and sheath (tubing) components. Our industry standard Thermocouples (J,K, E, T) have Tube and Wire construction, while some variations may include MgO insulation. See our Thermocouple Options

metals or alloys (commonly available as wire) that are welded together at one end to create the thermocouple Junction. It is the heating or cooling of the two metals that produce a voltage which can be correlated back to the temperature. More basically, thermocouples are the construction of wires and sheath (tubing) components. Our industry standard Thermocouples (J,K, E, T) have Tube and Wire construction, while some variations may include MgO insulation. See our Thermocouple Options

Thermocouple Applications:

Food processing equipment; de-icing; Plating baths; Medical equipment; Industrial processing; Pipe tracing control; Packaging equipment; Industrial heat treating; Refrigeration temperature control; Oven temperature control; and Liquid temperature measurement.

Thermocouple Characteristics:

-

Stainless Steel braid or hose protection

-

Lead lengths from 6 – 360”

-

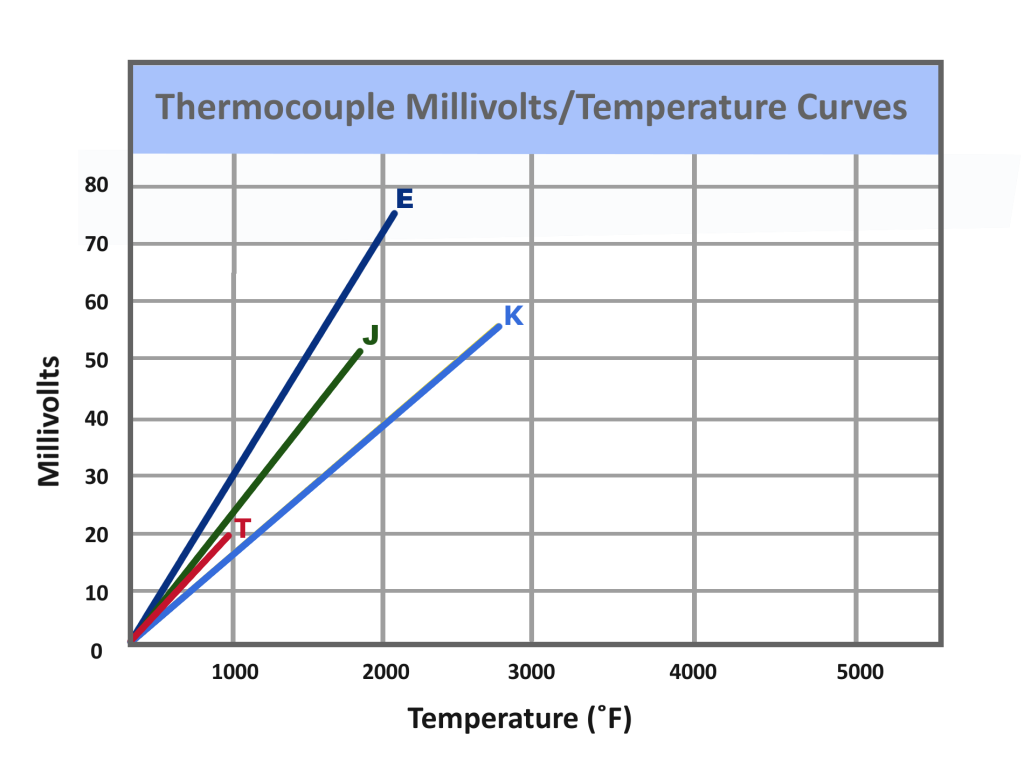

J,K, T and E calibrations

-

Ends may be epoxy sealed

-

Adjustable depths

-

Flat and drill point

-

Grounded, ungrounded and exposed junctions

-

Flexible extensions

-

Washers, nozzles and clamp bands

-

Custom diameters

-

PFA coated and stainless steel sheaths

-

Locking bayonet caps in standard and 12 mm

-

Straight 45˚ or 90˚ bend

Capabilities:

The fiberglass thermocouples can withstand temperatures up to 900˚F (480˚C) for continuous operation.

Calibrations:

Type E:

This calibration is best suited for temperatures up to 1650˚F (900 ˚C) in a vacuum, inert, mild oxidizing or reducing atmosphere. The thermocouple should outlive other types – when not exposed to corrosion, and when it has the highest EMF output per degree of other standardly used thermocouples.

Type J:

This design is the second most common of the calibration types. It is the suitable choice for general purposes where moisture is not present in its surrounding atmosphere.

Type K:

These thermocouples are the most common calibration for providing the widest operating range. They function well in most applications as they are primarily nickel based – aiding in corrosion resistance. This thermocouple can be used for applications up to 2300˚F (1260 ˚C).

Type T:

This type proves superior performance for its compatibility in numerous applications in low and cryogenic temperatures. And it is the best option for oxidizing or reducing atmospheres. The application of a protection tube is recommended to prolong the life of the thermocouple. The recommended operating range for this type is -330˚ to 660˚F (-200˚ to 350˚C) it can be used up to -452˚F (-269˚C).

Tolerances:

The flexible wire is insulated, and woven with fiberglass or high temperature resins. Stainless steel wire braid and flexible armor or common sheathing (tubing) are applied for abrasion protection of the inner sensing junction. Common mounting options are: springs, ring terminals, specialty bolts, and pipe style clamps and shims.

Resistance:

Resistance can’t confirm the alloy meets correct thermoelectric specifications, but it will check for additional unfavorable characteristics including: opens, poor welds, or wire corrosion. Therefore, be sure to measure resistance outside the application to ensure EMF output won’t conflict with the resistance meter.

Our Product Lines are US made. Call if you are in the area – and you would like to see our products: 513/228-0481.

Heat and Sensor Technology 627 Norgal Drive Lebanon, OH 45036